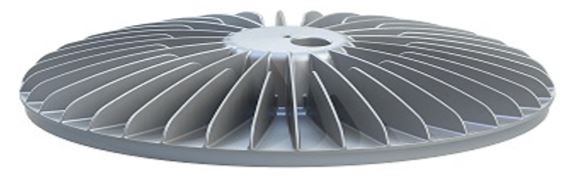

Housing

The custom-made driver is inserted into the uniquely designed housing, developed by experts in both aluminium high pressure die casting and heat management. The housing is made of quality alloy aluminium, which composition is specially designed for Intenz. The housing has been specially designed for optimal heat management; to direct the heat away from the critical areas of the driver.

Driver

The driver is made with best components available and engineered specifically for Intenz. The 600V current to the diodes gives the armatures 98% efficiency.

The driver is covered with an aluminium plate. The plate is permanently and seamlessly fastened with friction stir welding, which merges the plate into the housing by plasticising the two materials together.

Nichia LED

The diodes used are top-of-the-line Japanese Nichia LED. They are attached to the contact surface with self-adhesive, heat dissipative film, which as a material has proven to be more optimal compared to the more traditional heat dissipation paste.

The specially manufactured, individual optics are fastened to the printed circuit board, creating a 75° light spread.

Adding a fastening loop for the carbine hook, and a IP-67 classified plug-and-play outlet to retrofit any classical installation, the product has been completed.

For the final touch, every armature is individually and specifically tested for functionality and temperature (±4°C tolerance) before leaving the factory.

Simple installation

The smart design with integrated driver requires less material and creates great logistic advantages. In addition, the installation is simple as the installer does not have to deal with clumsy and heavy armatures that tag along a separate driver.

Less material means less environmental burden; optimal thermal management ensures savings in the energy bills.

The people responsible for safety and maintenance are happy to notice that the design is reliable and comes with a built-in emergency light function